Micro chip manufacturing

What is Micro chip manufacturing?

Micro 3D printing, also known as micromanufacturing, produces parts with extremely fine, micron-scale features. This emerging technology is gaining traction as a viable alternative to traditional manufacturing methods for creating high-precision components on a microscopic scale.

Metamiracle is advancing micro 3D printing with its 3D printers. These systems utilize a specialized method called projection micro-stereolithography, which enables the production of intricate structures with remarkable detail. The process strikes an effective balance between speed and quality, achieving feature resolutions as fine as a few microns. By delivering such precision, Metamiracle is paving the way for wider adoption of micro 3D printing in industries that demand highly detailed, small-scale components.

What are the uses of micro 3D printing?

Micro and nanofabrication have applications across numerous industries and research fields.

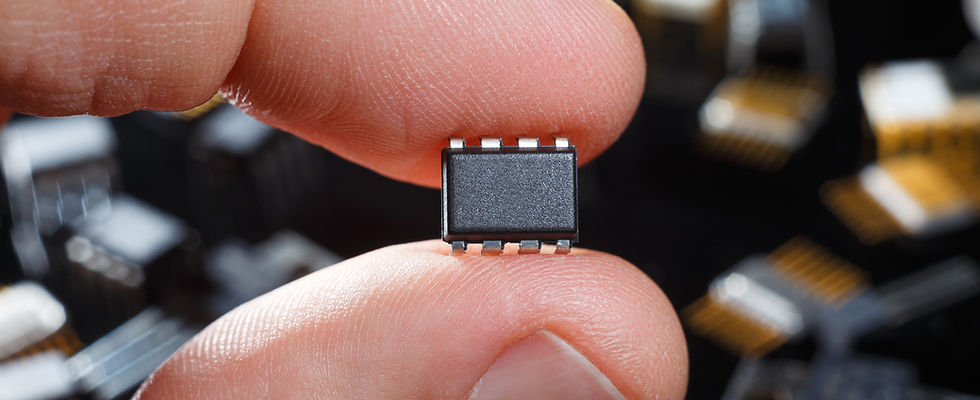

Electronic

Manufacturing of micro parts is employed to produce high-performance electronic devices, enabling size reduction, weight optimization, and the creation of precise, complex geometries.

Medical

Medical devices are becoming increasingly smaller and more complex to assemble. Micro 3D printing is instrumental in addressing these challenges and driving innovation. Our technology is well-suited for producing highly accurate micro medical devices.

Automotive

The automotive industry has increasingly adopted micro parts produced through micro manufacturing. Modern vehicles can contain up to 200 sensors, with Micro parts being used in various in-cabin components and numerous types of sensors.

Semicon

Micro manufacturing allows for the creation of advanced semiconductor components. This technology makes it possible to manufacture customized, geometrically complex parts that would be unachievable with traditional manufacturing methods.

Consumer Products

Micro printing are ideal for producing micro sensors used in wearable devices, as well as IoT sensors. The miniaturization and customization of small components are key to advancing the future of consumer product engineering.

Optics

Micro 3D printing has been utilized to create micro-lens holders, intricate lens assembly mounts, jigs, fixtures, and production tools. Customers can now achieve high definition, precision, and freeform surfaces that would be unattainable with traditional manufacturing methods.